WhatsApp)

WhatsApp)

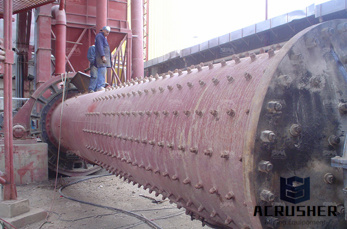

Ball mill working principle,Ball Mill for beneficiation product line. Powder is discharged through the discharge device, complete the milling operation.

ball mill operating costs. Milling solutions for coal power and industrial plants Alstom Prebeater option for improved mill capacity.

Processing of Magnetite Iron Ores – Comparing Grinding ... minimise operating costs, ... consisting of an AG mill followed by cobber magnetic

Mine Mill Equipment Costs Estimator''s Guide, Capital ... The following listings of equipment capital and operating costs are taken directly from the current Mining ...

Industry Standard for Mining Cost Estimating Mine Mill Equipment Costs Estimator''s Guide: Capital Operating Costs Over 3,000 mine and mill equipment items

and plant capital and operating costs. In the past 60 years, ... rod and/or ballmill circuits. ... Secondary crushing: worth the cost?

Stirred Milling 3 The Stirred Media Detritor (SMD) is a fluidized, vertical stirred mill designed for optimum grinding efficiency for fine and

capital and operating cost of ball mill for bauxite . Mine ore grinding mill used for mineral mining, processing plant Mine ore grinding mill is used for mineral ...

Ballmill Operational Parameters; ... ball mill operating parameters of ball mill ... The Zenith Mining Machine is custom designed to reduce your operating costs ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: Mark Simmons Production Manager Salt River .

Ball mill Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing ...

The high energy efficiency of stirred mills compared to ball mills is ... influence on mill parameters such as energy efficiency, internal wear and operating costs.

Ball Mill Low operating costs Stone Crusher Machine The design of this series was geared to optimized production, operating and maintenance costs. READ MORE.

Autogenous mills, semiautogenous mills and ball mills for wet grinding. ... Ball mill in iron ore bene ... ment and low operating costs:

A similar approach was applied to estimate the total direct costs. It was found that both HPGRball mill and HPGR ... a SAG millball mill operating in closed ...

Ball mills account for the majority of all mills in ... Optimizing the operation of the cement mill; Optimizing the ... Operational costs are expected to ...

Solutions for operating cost ball mill, Base on the latest technology and decades of years'' producing experience has wide application in secondary crushing of many ...

Optimisation of the secondary ball mill using an online ... as well as energy and media costs ... to correlate the ball load compactness with the mill operating and ...

As the largest equipment of mining plant,the ball mills operating state directly influences the whole mill plant productivity. Grinding ball mill is

ARE SAG MILLS LOSING MARKET CONFIDENCE ... including a high level discussion on capital and operating costs ... Different combinations of SAG mill ball charge and ...

ball mill crusher operational cost .. ball mill in regards to operating costs ... without failure with Low operating cost and Large capacity.

The energy saving ball mill is a horizontal cylindrical rotating device, which has two cabins. Ball mill is energy saving grate ball mill and the outside runs along ...

There are many different designs and styles of ball mill liners. As with grinding balls local economics and ultimately operating costs determine the best design and ...

Grinding Cost Analysis. ... accounted for 30% in overall mineral operating costs, ... production integration,it covers about 50% of the area of the ball mill system;

WhatsApp)

WhatsApp)